Why Is CAD Essential For Modern Aerospace Design?

If you’re looking to evaluate your design capabilities and wondering ‘Why is CAD essential for modern aerospace designs?’, this is the blog for you. We will go over what CAD systems are, current trends in the aerospace industry, and how CAD can help you achieve superior designs. Continue reading to find out more.

What Is CAD In Aerospace Design?

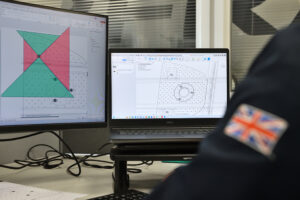

The inclination toward computer technology has been merged with traditional design concepts, to bring forward Computer-Aided Design. CAD plays an essential role in aerospace drafting and design.

Using advanced software, aerospace engineers can achieve precision, accuracy and adherence to strict safety standards.

CAD helps to accelerate the process of innovation, by using past-aerospace models as a starting point to conceptualise ideas and identify areas for improvement.

By using CAD software, designers can create two or three-dimensional computer-generated models or frames, objects, products, or structures. These virtual models intend to accurately depict the physical dimensions, characteristics, and properties of an object.

Designs made via CAD are easily rotated and viewed from different angles and can be subject to simulations and tests to evaluate their performance. Design flaws and revelations are easily detected with the help of computerised design systems.

Demands Of Modern Aerospace Design

The aerospace industry continues to evolve year-on-year. Technologies are constantly being innovated that challenge our current norms. Emerging trends in the aerospace industry mean CAD is essential for modern aerospace design. Some of the benefits include:

- Autonomous Flight Sytems– Autonomous ground vehicles already exist on our roads. We are even seeing it become more prevalent in the skies. Drones have achieved autonomous navigation, so the natural trajectory of this trend is toward aerospace design.

- Additive Manufacturing– More aerospace engineers are reaping the benefits of additive manufacturing. Additive manufacturing is a process that allows engineers to create physical objects by adding material in layers, essentially ‘printing’ CAD designs.

- Artificial Intelligence– AI is widely being used in the aerospace industry to improve fuel efficiency, design, inspection processes, maintenance, repair, and overhaul. Furthermore, AI enables the innovation of aircraft engineering capabilities to operate fully or semi-autonomously.

- New Materials– The demand for new materials in the aerospace industry is ever-growing. New design developments and requirements are unachievable without heat-resistant and lightweight alloys. Advanced materials can improve the aerospace industry’s environmental impact.

Benefits That Make CAD Essential For Modern Aerospace Design

CAD systems have revolutionised aerospace design. With its numerous benefits, it has accelerated the efficiency, accuracy, and innovation of design processes. It is an essential asset for modern aerospace design. Here are some of the key benefits:

1. Enhanced Precision And Accuracy

By utilising CAD systems, designers can achieve more precise, detailed, and accurate models. More enhanced precision eliminates the chance of errors or miscalculations in design, resulting in higher-quality concepts and performance in aerospace design.

2. Improved Simulation

For the analysis process, CAD facilitates 3D modelling, which helps designers to visualise the product more clearly. Models will undergo simulations of physical conditions and scenarios, such as aerodynamics, thermal dynamics, and stress analysis, to see how the design endures the environment.

3. Efficiency And Speed

By automating repetitive tasks, the process becomes much quicker. Modifications to design can be made swiftly. Conceptualisation, to testing, all the way to production becomes a more streamlined and efficient process with the integration of CAD systems.

4. Cost Reduction

The process of design and analysis can require a lot of alterations. Using CAD systems lessens the amount of material waste, due to the reworking of designs. By simulating and testing designs virtually, there is less of a need to create physical prototypes, which can be labour-demanding and costly.

4. Ease Of Collaboration

By hosting design on a virtual domain, teams can easily collaborate on the process, despite not being in the same place. Data can be easily shared, reviewed, and modified, all in real time. CAD systems may improve communication across departments and with external clients.

5. Enhanced Documentation And Compliance

Using CAD software, design engineers can achieve comprehensive documentation capabilities, such as detailed sketches, bill of materials, and technical specifications. As the aerospace industry revolves around stringent regulations, enhanced documentation makes it easier to achieve the industry standard.

6. Historical Data Retention

CAD systems make it easier to store and organise historical data. Relocating files can be done with ease and keeping a record of data changes may improve your design process.

Why Is CAD Essential In Modern Aerospace Design?

Aerospace design requires complex geometrics that can be difficult to conceptualise or draw manually. Human error in aerospace design can be costly. Integrating CAD systems allows for better intricacy, which is a necessity for successful modern designs.

At Airframe Designs, we are highly familiar with several CAD systems, including CATIA, Siemens NX, Solidworks, Inventor, and CREO.

We are constantly striving to expand our capabilities and ensure our team is well-equipped with the skillset and training to use advanced CAD tools, drive innovation, and achieve excellence in our project.

Our design capabilities using CAD for aerospace help deliver reliable 3D models and 2D datasets, enabling the manufacture of mechanical products. We also provide support in reverse engineering, design for additive manufacturing, and legacy data digitisation.

If you would like to know more about the CAD systems we use, or are interested in collaborating with Airframe Designs, please don’t hesitate to contact us.