Airframe Designs is proud to announce the acquisition of a cutting-edge five-axis CNC machine from 5AxisMaker, enhancing our suite of high-precision additive manufacturing equipment. This sophisticated machine has an internal working area of 600x600x600mm, equipped with a versatile set of tools including a 15,000 RPM spindle and an FDM extruder.

This addition enables us to excel in polymer part finishing, model board machining, accurate hole drilling, and lightweight tooling with high levels of accuracy. Furthermore, the machine’s capabilities in surface machining and finishing ensure that we can achieve the tight tolerances required by the aerospace, defence, and space industries.

By integrating the 5AxisMaker CNC machine alongside our existing additive manufacturing fleet, which includes two Stratasys Fortus 450mc machines, a BCN3D Epsilon W27, a Builder Extreme Pro1500, two Bambu Labs X1E machines, and a FormLabs Form3 Plus, we’re pushing the boundaries of what’s possible in aerospace manufacturing.

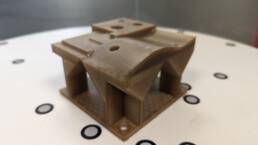

Our commitment to precision and quality is further demonstrated through the customisation of the 5AxisMaker machine. Utilising our additive manufacturing technology, specifically Siemens NX CAD and DfAM software, and our Bambu Labs X1E printers, AFD has created stiffening brackets to enhance the machine’s stability and precision.

Additionally, our capabilities for precise component positioning during machining have been significantly enhanced by the inclusion of a custom-made aluminum machine bed. This precise placement capability significantly improves the quality and consistency of our machined parts, by ensuring optimal alignment and orientation during the machining process. This is crucial for achieving the superior tolerances and finishes that our clients demand.

This strategic expansion into CNC machining complements our existing additive manufacturing solutions, offering our clients a comprehensive service portfolio capable of producing components with tighter tolerances and superior finishes. The acquisition of the 5AxisMaker CNC machine is a testament to Airframe Designs’ dedication to innovation, quality, and the continuous pursuit of excellence in engineering.

This strategic enhancement underscores Airframe Designs’ commitment to leading aerospace innovation and precision manufacturing.

Recent projects undertaken by Airframe Designs include the design and manufacture of several 3D printed tooling fixtures to aid the installation of external sensors onto the fuselage of a special mission military aircraft and the integration of new systems into heavy lift drone platforms.

The company has also been responsible for the conceptual design at a platform level for new uncrewed air-systems, test rig and tooling for electric vehicle propulsion systems and most recently the design and analysis of operator consoles for a special mission aircraft.

For more information contact Airframe Designs, tel 01253 400320 or visit the Airframe Designs website.