Certification

We assist external organisations in the classification of changes and repairs and subsequently peer review the elected certification basis, certification plans, and compliance demonstration evidence, all in the capacity as Structures Compliance Verification Engineers (CVEs).

We also visit test facilities to witness and verify test activities that underpin certification, and hold regular dialogue with the competent authorities.

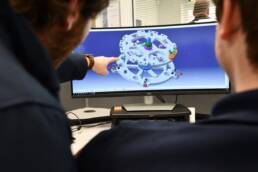

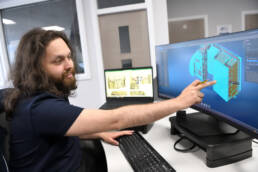

Additive Manufacturing

Our focus is additive layer manufacturing of polymer parts, prototypes, trial-fit mock-ups, and lightweight tooling.

Our facility houses an array of FDM printers and ancillary equipment including a Stratasys Fortus 450mc for printing ultra-polymer materials.

We utilise a hand-held laser scanner for product geometry validation and for reverse engineering or surveys.