Airframe Designs Invest in Advanced MRP System.

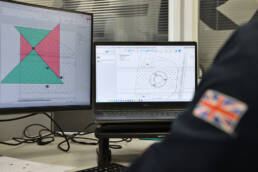

At Airframe Designs, we are committed to leading the aerospace industry through continuous investment in cutting-edge technologies. Our latest advancement is the implementation of Progress Plus, a state-of-the-art Materials Requirements Planning (MRP) system. This strategic investment is designed to streamline our operations, enhance supply chain efficiencies, and deliver substantial time and cost savings to our customers.

The integration of Progress Plus will revolutionise our approach to purchasing, stock control, quotations, and manufacturing. This system ensures data accuracy, transparency, and seamless communication across all operational functions, significantly improving our process efficiencies.

Jerrod Hartley, our CEO, commented on this transformative step: “The integration of this advanced system marks a transformative step for Airframe Designs and our customers, helping us to leverage efficiencies in our processes and allowing for improved collaboration with partners and suppliers. Custom-designed to complement our unique operational framework, this software investment is pivotal to our commitment to data confidentiality, integrity, and availability delivering direct, substantial benefits to our customers.”

In addition to our investment in the MRP system, we have further enhanced our advanced production facility. We have acquired a second 3D printing machine, the state-of-the-art Stratasys Fortus 450mc, a new five-axis milling machine, and sophisticated resin printing technology. These additions enable us to offer increased capability and higher quality parts and tools to our expanding customer base.

Our membership in Additive Manufacturing UK (AM-UK) reflects our dedication to establishing the UK as a global leader in additive manufacturing. The services we offer meet the aviation and defence sectors’ demand for creating new parts or re-engineering obsolete ones in an agile, cost-effective, and sustainable manner.

With our advanced polymer additive manufacturing technology, combined with 3D scanning and 3D modelling, we now offer innovative solutions to complex engineering challenges. These technologies serve the aviation and defence sectors and can be adapted for other industries, including space, nuclear, motorsport, and rail.

Our recent projects showcase our capabilities. We have designed and manufactured several 3D printed tooling fixtures to aid the installation of external sensors on the fuselage of special mission military aircraft and integrated new systems into heavy lift drone platforms. Additionally, we have been responsible for the conceptual design at a platform level for new uncrewed air systems, test rig and tooling for electric vehicle propulsion systems, and the design and analysis of operator consoles for special mission aircraft.

At Airframe Designs, our focus is on delivering innovative engineering solutions that meet our customers’ evolving needs, maintaining our position as a leader in the aerospace industry.