Introduction

AFD was tasked to create a fixture for an aircraft to correctly position an external sensor. This would be done using AFD’s modelling, manufacturing and scanning skills. This fixture would be used on a Intelligence, Surveillance and Reconnaissance (ISR) aircraft.

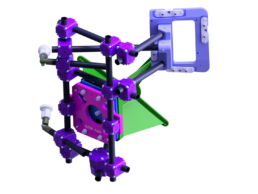

A significant aspect of the engineering challenge was designing the fixture to securely attach externally to the aircraft while meeting the precision required for mounting an external component.

Manufacturing

The manufacturing goal was to deliver a cost-effective, lightweight fixture, with a rapid turnaround for both design and production. The components were produced using aerospace-grade Stratasys Fortus 450 additive manufacturing machines, enabling fast lead times and cost-efficient production.

The fixture utilised Nylon CF, a cost-effective alternative to metallic materials, offering exceptional strength and stiffness—making it ideal for tooling applications.

Additionally, carbon fibre composite tubing was incorporated for its lightweight properties and adaptability. These tubes seamlessly integrated with the additive manufactured components, leveraging the rapid prototyping capabilities of advanced additive manufacturing machines.

This approach ensured the functionality of components was validated efficiently, avoiding the need for time-consuming and resource-intensive remakes.

Inspection

Each component of the ISR Aircraft Sensor Location Fixture underwent rigorous inspection using advanced 3D scanning technology. The scanned data was then analysed with inspection software, such as Verisurf, to generate detailed reports on any deviations from the original design. This process ensures all parts meet the specification with speed and accuracy.

Using Verisurf, we compared the scanned model to the original CAD file, providing both a visual representation and a comprehensive inspection report. This allows our clients to receive parts that have been thoroughly inspected to the highest standards, delivered efficiently and reliably.

AFD delivered a comprehensive turn-key solution for the fixture, surpassing expectations and achieving exceptional results with rapid lead times, cost efficiency, superior quality, high performance, and full compliance.

Click the link to read the full case study: www.airframedesigns.com/portfolio/isr-aircraft-sensor-location-fixture/

Looking to streamline your projects with additive manufacturing solutions?

Get in touch with us today: www.airframedesigns.com/contact-airframe-designs/