Introduction

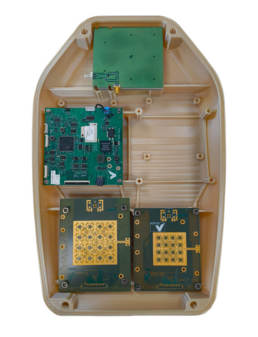

Airframe Designs was engaged by ReliaSat, a global leader in satellite communications, to provide design, manufacturing and scanning expertise for a satellite communication radome antenna combined with a terminal to house the electronical steered array (ESA) boards, military grade GPS, and ancillary electronics.

Design Approach

The design team embarked on evolving and optimising a DfAM (Design for Additive Manufacturing) solution using ultrapolymer material to deliver the smallest footprint, frontal area and aerodynamic profile, whilst also packaging the equipment with sufficient ventilation and separation within the radome.

Manufacturing Process

To meet the specifications required within aerospace and defence products, the manufacturing process utilised our Stratasys 450mc with ULTEM 9085. The material and control processes within our Production facility ensure products are manufactured to the highest quality.

Inspection Process

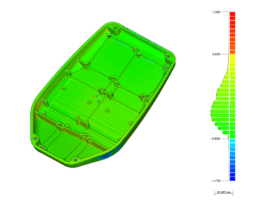

The radome was rigorously inspected post-manufacture, to compare the printed geometry with the design intent (CAD model).

This was done by utilising a 3D scanner to input the printed geometry into our inspection software. A combination of Verisurf and Siemens NX software was utilised to create an inspection report that included a visual display of the tolerances achieved for the part versus acceptance criteria.

Conclusion

Through Design, Manufacturing and Scanning expertise, AFD showcased a high level of skill and experience, delivering a high standard for the customer. Click the link to read more.

https://airframedesigns.com/portfolio/satcome-antenna-radome/

Click the link below to discuss how we may be able to help with your bespoke engineering challenges.