Innovations in aerospace design are in a constant state of evolution, driven by technological advancements. With the introduction of artificial intelligence, autonomy, and other technologies – aerospace design really is taking off! Cutting-edge technologies have shaped the future of aerial combat, guiding further innovations when it comes to modern fighter aircraft. In this Airframe Designs blog, we delve into some of the most notable innovations in aerospace design for modern fighter aircraft, showcasing how these developments are redefining the field.

We’re also going to look at some of the innovations emerging from BAE Systems, and the Tempest and GCAP programmes, as this work encompasses some of the most exciting current developments in the UK.

Aerospace Design Innovations For Modern Fighter Aircraft

Sure, aerospace design in general is a huge sector to navigate, and there are innovations and trends emerging continuously – but what about specifically focusing on military aircraft? Let’s explore some of the aerospace design innovations we are expecting to become popular, specifically related to modern fighter aircraft.

Stealth Technology

Stealth Technology

Stealth technology, simply speaking, refers to the process of making modern fighter aircraft invisible to radar. This technology has undoubtedly revolutionised aerospace design for defence and military aircraft, enabling them to operate with reduced radar visibility. There are a number of ways to achieve stealth aircraft design including, advanced materials, unique shapes, and precise surface treatments, which are important for making these aircraft more difficult to detect and track – useful for modern fighter aircraft.

Digital Twin Technology

A digital twin is a virtual replica of a real device, product, or entity – or when it comes to aviation, an aircraft. An exact digital replica of an aircraft has several uses, but the most relevant for the sake of this article is how the use of digital twin technology will aid the manufacturer of aviation components.

Already in use by BAE Systems, MBDA, Rolls Royce and Leonardo, the technology allows engineers to install sensors on physical aircraft and then use the digital twin to improve aircraft and run simulations they wouldn’t be able to on a real aircraft. Engineers usually rely on probability, but a digital twin means they can instead fine-tune craft based on real data.

Thrust Vectoring

Thrust vectoring, a technology adopted by NASA, is a technology that allows fighter aircraft to manipulate the direction of their flight. This is specifically important for aircraft used in defence which require greater manoeuvrability and agility. If you have ever seen a fighter aircraft perform astonishing manoeuvres – it is most likely due to thrust vectoring! This innovation in aerospace design allows pilots to be tactical in high-pressure situations.

Unmanned Combat Aircraft

The rise of unmanned combat aircraft, or drones as you may more commonly know them, has been a game changer in modern defence aerospace. For those missions that may be too dangerous or taxing for human pilots, remotely piloted aircraft which we refer to as unmanned combat aircraft tend to be used. The rise of unmanned combat aircraft continues to evolve rapidly with the integration of artificial intelligence (AI) and autonomy in fighter aircraft design.

Hypersonic Aircraft

Military across the globe continue to advance and evolve the design of hypersonic aircraft. This type of modern fighter aircraft has the ability to travel at great speeds. Those in the aerospace design industry are anticipating hypersonic aircraft to completely revolutionise global military capabilities. Creating an aircraft with rapid response times and unprecedented speeds, as we see with hypersonic aircraft, is a huge leap forward when we look at innovations in fighter aircraft design.

Advanced Manufacturing

Advanced manufacturing refers to the use of innovative technologies and methodologies to improve products and processes in the production environment. Advanced manufacturing has been embraced by the aerospace industry, particularly advanced manufacturing techniques such as 3D printing which allows for the fast reproduction of components at better value. 3D-manufactured components are right now helping protect UK airspace by being flown on the RAF’s fleet of Typhoons!

FCAS, Tempest And GCAP

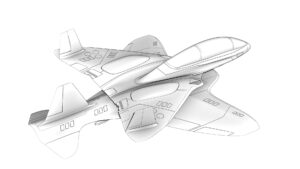

Of course, we can’t talk about innovations in aerospace design and modern fighter aircraft without discussing the UK’s Future Combat Air System (FCAS), which involves the Tempest project and the final Global Combat Air Programme (GCAP).

FCAS and GCAP are related but separate projects – FCAS are working towards the development of a piloted supersonic fighter demonstrator, whilst GCAP is a partnership between the UK, Italy and Japan to develop a sixth-generation fighter which will meet the needs of all three nations’ requirements, and eventually replace the RAF’s fleet of Typhoons.

Tempest is the fighter demonstrator or research and development project that the UK plans to first fly in 2027. GCAP is the finished project that will be delivered to the RAF – predicted to be in 2035.

Although we are some way off seeing GCAP enter service, there has been plenty of publicity around the work already undertaken by companies such as BAE Systems. BAE’s ‘factory of the future’ in Warton, Lancashire, plays a pivotal role in the project. While the specific locations for the final assembly and full-scale manufacturing of the future fighters remain to be confirmed, this facility is anticipated to be a significant contributor to the production process. The futuristic factory has extensively invested in cobotics – the collaboration of people and robotics in manufacturing which has already been tested on current fighter jets.

One of the exciting innovations emerging from the Tempest project is the so-called ‘cockpit of the future’ which will see most of the Tempest’s physical controls gone – instead, augmented-reality and virtual-reality (AR and VR) systems will be projected directly inside the visor of a pilot’s helmet. The new ‘wearable cockpit’, already in development by BAE will mean as technology advances, aircraft will no longer have to be grounded for updates to hardware – as the software in the wearable cockpit can be updated instantaneously.

Tempest will rely on digital technology more than any other aircraft – the Tempest project is often referred to as a ‘system of systems’ because the project is composed of a main platform (the aircraft itself) and other airborne systems, including unmanned aircraft. These can all talk to each other in real time because of cloud technology, the goal being operations that can be adjusted quickly in changing scenarios.

Advanced sensors and effectors are also key components of Tempest’s cutting-edge design – advanced sensors integrated with the aircraft will mean information can be exchanged quickly on potential battlefields via a ‘combat cloud’. Effectors integrated into the Tempest’s sensors will mean the fighter jet can engage in non-kinetic effects such as enemy radar jamming.

This is just a brief look at some of the innovations happening in FCAS, Tempest and the GCAP programme. The British-led initiative is one of the UK’s largest-ever science and technology endeavours, involves over 600 companies, and will deliver world firsts in advanced technical capabilities.

Modern Fighter Aircraft With Airframe Designs

At Airframe Designs, our team has extensive experience across many military platforms and programmes and an in depth knowledge of modern fighter aircraft and the upcoming innovations taking the industry by storm.

It is no secret that the innovations in aerospace design for modern fighter aircraft are reshaping the future of aerial warfare. The advancements we have explored in today’s blog are just the tip of the iceberg when it comes to the evolution of fighter aircraft.

If you want to know more about the work we do with modern fighter aircraft or discuss innovations in aerospace design with a member of our team, feel free to contact us!

You can reach us by calling 01253 400320 or emailing reachout@airframedesigns.com.