Task Objectives

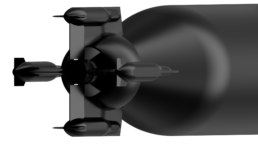

Airframe Designs was engaged by a global defence prime to produce a mock-up of a large torpedo style weapon (store), within a very short time frame.

The project required the artifact to not only serve as a physical representation but also to facilitate the evaluation of its integration onto a new delivery platform.

The goal was to assess various critical aspects such as feasibility, accessibility, and safety considerations when offering up and installing the store on to the platform.

Demonstrating our commitment to excellence and our ability to provide bespoke turn-key solutions, we delivered a high-quality product that met all the client’s needs underscoring our position as a dependable and innovative partner to some of the world’s foremost defence manufacturers.

Design for Additive Manufacturing

The 2.7m long mock-up was designed for additive manufacturing (DfAM) by highly experienced engineers to meet the customer requirements, ensuring the optimal solution was achieved.

The key for the DfAM process was to create a lightweight, robust and stiff structure using low-cost material and rapid prototype printers.

Appropriate torsional and bending stiffness was introduced by incorporating internal helical cojoined and continual members.

Additive Manufacturing Approach

The manufacturing methodology involved segregating the product into several discrete longitudinal sections, prior to assembly.

Each section was printed on our Stratasys Fortus 450mc industrial aerospace FDM machine using ASA thermoplastic to provide tough and durable parts.

Conclusion

The computer-aided design and manufacturing of the mock-up was completed in just 10 days, exceeding the customer expectations for on-time delivery and product quality.

We thrive on providing bespoke solutions engineered and crafted specifically to help our customers reduce their project lead times and improve their cost-effectiveness.

Providing high quality solutions to complex engineering and manufacturing challenges is what exemplifies AFD.

Testimonial

Head of Weapon System Integration

“This was our first engagement with an external supplier for polymer additive manufacturing and proved to be a very successful route for gaining access to an agile design and build partnership for rapid prototyping and mock-up needs.”