Task Objectives

Airframe Designs was approached by a UK company that specialises in the design and manufacture of high value aerospace and defence antenna systems.

The customer was seeking a technology partner to help in the development and supply of a new polymer radome, manufactured using additive layer technology in order to reduce cost and improve Radio Frequency (RF) performance.

Design & Engineering Challenges

The radome had to satisfy several critical requirements to meet a challenging technical specification for a US based end-user.

First; it needed to be radar permeable, meaning the material and geometry had to allow radar signals to pass through.

Second: it had to possess sufficient structural integrity to withstand the aerodynamic loads encountered during flight.

Finally; as a flightworthy part, the radome was required to be manufactured using aerospace-certified materials and processes to ensure compliance with industry and airworthiness standards.

Technical Approach

To meet certification standards, the radome was produced using a Stratasys Fortus 450mc 3D printer with ULTEM 9085CG, a high-strength engineering thermoplastic known for its excellent mechanical properties and compliance with aerospace regulations (CG Grade).

Multiple design iterations were undertaken to optimise radar transparency and mechanical performance. Each iteration was evaluated for signal transmission characteristics and structural resilience, ensuring the final design met all operational requirements.

This included altering the shape and thickness of the radome and leveraging AM’s potential for part count consolidation by incorporating the base plate into the design reducing a 2-part assembly to a single piece.

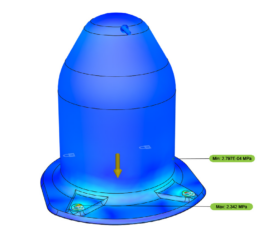

The radome was analysed for static strength using B-basis material strength properties, prior to completing a physical static test at loads above and beyond the technical requirements.

Inspection

Each 3D printed part was rigorously inspected post-manufacture, to compare the printed geometry with the design intent (CAD model).

A combination of Verisurf and Siemens NX software was utilised to create an inspection report that included a visual display of the tolerances achieved for the part versus acceptance criteria.

Conclusion

The radome finished product exceeded expectations, showcasing our pursuit for innovation and excellence. By leveraging our expertise, we not only adhered to the project’s specifications and timelines but also introduced advanced solutions that set new standards in quality and performance.

We thrive on providing bespoke solutions, engineered and crafted specifically to help our customers reduce their project lead times and improve their cost-effectiveness. Providing high quality solutions to complex engineering and manufacturing challenges is what exemplifies AFD.

Testimonial

Head of Production

“Airframe Designs delivered a flightworthy radome that exceeded our expectations. Their expertise in additive manufacturing and materials ensured radar transparency, structural integrity, and compliance. The final product was innovative, cost-effective, and met all technical requirements on time.”