Task Objectives

AFD was approached by Multi-Ply (medical equipment OEM) to provide expertise in design, analysis, and additive manufacturing to support the development of a medical imaging table.

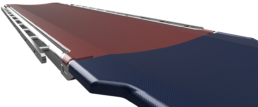

The engineering challenge associated with the task objective was to derive a unique table joint for a split table design that would be simple to use, easy to manufacture, have minimal joint protrusion, and be aesthetically pleasing. All of these requirements had to be achieved whilst ensuring structural integrity.

Design & Stress Analysis

The AFD design team created a unique table joint that is now patented and recognised for its novelty, in accordance with the customer requirements.

Stress analysis was undertaken in parallel with the design activity to ensure that the table joint would be structurally safe whilst minimising weight and complying with industry standards.

A composite lay-up was derived and developed using classical laminate theory, hypersizer software, and finite element modelling to generate an optimised ply lay-up and stacking sequence.

Rapid Prototyping

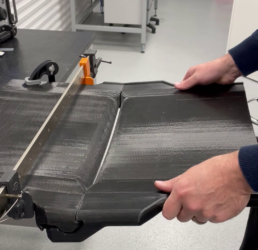

The AFD manufacturing team utilised advanced Additive Manufacturing to create a mock-up model of the removable table and associated joint using thermoplastic materials.

Due to the high level of precision, mock-up models were manufactured as a physical check of conceptualised designs, to ensure acceptable fit, form and function.

AFD is proud that the mock-up model was later demonstrated at an overseas trade show, serving as a testament to excellence in engineering and our customer-focused approach.

Patent Pending

Submitting our first patent application through the UK Intellectual Property Office marked a significant milestone for Airframe Designs, emphasising our dedication to innovation.

This experience in patent applications taught us invaluable lessons about protecting our designs and enhancing our competitive edge.

The successful patent of the unique table joint will not only strengthen our market position but also lays a strong foundation for future intellectual property strategies in our industry partnerships.

Conclusion

The design and rapid prototyping of the table joint was completed in accordance with customer requirements and within the allocated timeframe.

We thrive on providing bespoke solutions engineered and crafted specifically to help our customers reduce their project lead times and improve their cost-effectiveness.

Providing high quality solutions to complex engineering and manufacturing challenges is what exemplifies AFD.

Testimonial

Technical Director

“I am very happy with the support provided by AFD in the development of the hinge design for the split medical table. AFD brings skills, competency, and cross-sector experience that we do not have in-house, providing an ideal partnership for the creation of strong and lightweight structures.”