Task Objectives

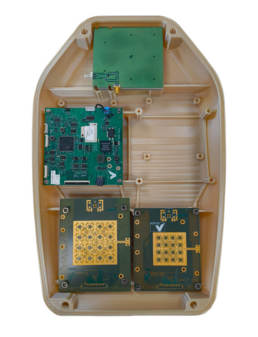

Airframe Designs was engaged by ReliaSat, a global leader in satellite communications, to provide design, manufacturing, and scanning expertise for a Satellite Communication (SATCOM) radome antenna combined with a terminal to house the electronical steered array (ESA) boards, military grade GPS, and ancillary electronics.

The requirement was to create a lightweight, robust, stiff, and affordable radome/chassis to accommodate equipment, whilst also enabling RF transmission, and delivered in a short timeframe.

Design Approach

The design team embarked on evolving and optimising a DfAM (Design for Additive Manufacturing) solution using ultrapolymer material to deliver the smallest footprint, frontal area and aerodynamic profile, whilst also packaging the equipment with sufficient ventilation and separation within the radome.

In addition, the team created adequate stiffening within the radome to assure strength and rigidity. By adopting this approach and choosing this method of manufacture and material the team was able to meet the technical requirements but also deliver the product over a very short lead-time compared with traditional manufacturing approaches.

Manufacturing Process

To meet the demanding specifications required in aerospace and defence for flightworthy products, the chosen manufacturing process and material quickly converged towards the use of our Stratasys Fortus 450mc with ULTEM9085.

The material and process controls within our Part21G Production Organisation facility assure a high-quality product, offering exemplary performance in terms of excellent strength- to- weight ratio, high Tg parameter, and superior RF transparency compared with other materials.

Inspection Process

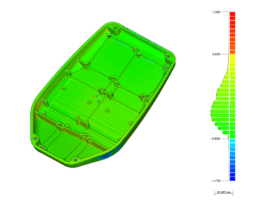

The radome was rigorously inspected post-manufacture, to compare the printed geometry with the design intent (CAD model).

This was done by utilising a 3D scanner to input the printed geometry into our inspection software. A combination of Verisurf and Siemens NX software was utilised to create an inspection report that included a visual display of the tolerances achieved for the part versus acceptance criteria.

Conclusion

The design, manufacturing and inspection of the radome was completed in accordance with customer requirements and within the allocated time.

We thrive on providing bespoke solutions, engineered and crafted specifically to help our customers reduce their project lead times and improve their cost-effectiveness. Providing high quality solutions to complex engineering and manufacturing challenges is what exemplifies AFD.

Testimonial

Head of Production

“Working with Airframe Designs was a gamechanger. Their deep understanding of additive manufacturing within aerospace enabled us to achieve a radome that hit every mark—lightweight, radar-transparent, structurally sound, and fully compliant. Delivered on schedule and within budget, the solution not only met our technical needs but also pushed the boundaries of innovation.”