Additive Manufacturing

At Airframe Designs, we focus on additive layer manufacturing of polymer parts, prototypes, trial-fit mockups, and lightweight tooling.

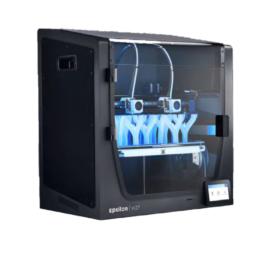

Our advanced manufacturing facility houses an array of FDM printers and ancillary equipment, including a Stratasys Fortus 450mc for the production of ultrapolymer materials such as ULTEM 9085.

We utilise a hand-held laser scanner for inspection (part geometry validation), undertaking airframe surveys and reverse engineering.

Innovating through Partnerships

We are actively involved in technological innovation and R&D through our partnerships with industry specialists in advanced manufacturing, Universities and Research Centres. This means that we can actively incorporate these technological advances to benefit our work and our offering to our customers.

AM Manager - Garry Sellick

An experienced manufacturing engineer with a significant practical background in engineering.

Most recently, Garry gained a first class degree in Automotive Performance Engineering at the University of Bolton, followed by a period of employment by the university in supporting the development of a new additive manufacturing research centre.

With over 18 years’ of manufacturing experience in the injection moulding sector, Garry is a highly skilled analytical engineer with an aptitude for developing and implementing solutions to manufacturing issues.

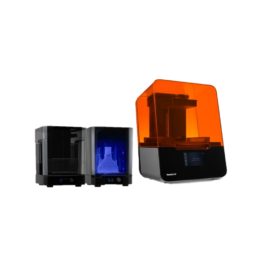

Garry is familiar with a wide array of additive manufacturing technologies for both polymer and metallic materials and is skilled in using Fused Deposition Modelling (FDM), Laser Powder Bed Fusion (LPBF), and Stereolithography (SLA) systems.

At AFD, the remit for Garry is to lead the development and growth of the manufacturing team and production facility, working closely with our design, stress and certification specialists to enable the delivery of optimum products to a diverse customer base.

The Impact of Our Technology

The adoption of these technologies not only enhances our manufacturing capabilities but also offers significant benefits:

Reduced Lead Times: Accelerating the journey from concept to product, ensuring faster delivery to market.

Improved Quality: Achieving superior precision and reliability in every part produced.

Environmental Benefits: Our additive manufacturing processes are designed to minimize waste and energy consumption, contributing to more sustainable production methods.

Cost Efficiency: By optimising production processes, we can reduce life-cycle costs for our clients, making high-quality manufacturing accessible.

Why Choose Airframe Designs?

Our additive manufacturing capabilities are tailored to meet the high standards of the aerospace sector and beyond. Whether you’re looking for durable lightweight tooling, intricate prototypes, or innovative manufacturing solutions, Airframe Designs has the expertise and technology to make it happen.

Discover how our advanced additive manufacturing capabilities can transform your project. Contact us today.