Introduction

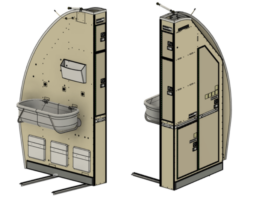

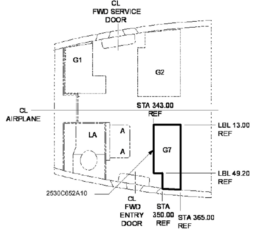

Airframe Designs was tasked by RAS Interiors to compile a static strength substantiation for a BOEING 737NG Windscreen Stowage. The part is located at the forward entrance of the passenger cabin and so one of its functions is to serve as a windscreen. The objective was to ensure the part met all the necessary airworthiness regulations when pertaining to static strength.

Finite Element Modelling

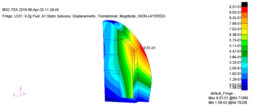

A Finite Element Model (FEM) of the part was created using MSC software (NASTRAN solver). The model was loaded using critical design inertia cases (9g FWD and 3g SIDE Emergency Landing Conditions / UP and DOWN Gusts) and critical passenger abuse cases per EASA CM-S-009.

Static Strength Substantiation

The strength of the panels was processed using the MSC software. panel facings were checked against the Tsai-Hill composite failure citron. The panel NOMEX core was checked through-thickness shear using HEXEL allowables.

Metallic reinforcing blocks bonded and fastened into the composite carcass were analyses using hand calculations in MATHCAD, balancing the interface loads back into the unit.

Items of mass like emergency equipment and stowage accessories were assessed separately to ensure adequate retention.

Interface Loads Analysis

The FEM included spring elements at the interfaces between the unit and the airframe. Ultimate interface loads were extracted from the FEM and compared with allowable interface loads per the OEM D6 specification, inclusive of the 1.33 wear and tear factor per EASA CM-S-002.

Conclusion

Through structural analysis, AFD showcased a high level of skill and experience, delivering a high standard for the customer. Click the link to read the full case study.

www.airframedesigns.com/portfolio/boeing-737ng-windscreen-stowage/

Click the link below to discuss how we may be able to help with your bespoke engineering challenges.