Introduction

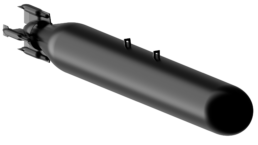

Airframe Designs was tasked by a global defense prime to create a mock-up of a torpedo styled weapon store within a short amount of time. The mock-up was required to be a physical representation to evaluate the designs integration onto a new delivery platform.

This allowed for many variables such as feasibility, accessibility and safety to be easily considered when installing the mock-up to the platform.

Design For Additive Manufacturing

Although the mock-up was 2.7m long, it was entirely made through additive manufacturing. The mock-up was designed for additive manufacturing (DfAM) ensuring the optimum solution was achieved through this manufacturing process.

The DfAM process made the mock-up lightweight, robust and stiff whilst keeping the cost low. This included the internal helical features which gave the mock-up the required stiffness without increasing the overall thickness of the part.

Additive Manufacturing Approach

The mock-up was split in the DfAM process into sections which could fit on to our additive manufacturing machines. To create the final mock-up, the sections were built on our Stratasys Fortus 450mc industrial FDM machines using ASA thermoplastic. This provided a tough and durable mock-up.

Conclusion

Through design and manufacturing, AFD showcased a high level of skill and experience, delivering a high standard for the customer. Click the link to read the full case study.

www.airframedesigns.com/portfolio/full-scale-weapon-mock-up/

Click the link below to discuss how we may be able to help with your bespoke engineering challenges.