Task Objectives

Airframe Designs was engaged by AIRBUS to perform stress analysis for the Type 4A Basket.

This particular basket is a ‘static’ basket and forms part of a family of six different Human External Cargo (HEC) baskets that have been designed for use across France and Spain in combination with a H135 helicopter.

Static baskets are designed to be ferried to power lines, detached from the helicopter in order to carry out the necessary repair or maintenance activity, and then collected later and returned to base.

Non-Human External Cargo?

EASA imposes specially written regulations for carrying human external cargo beneath helicopters: CS 27.865 – External Loads, paragraph (c).

These regulations require the design to meet a more rigorous set of static strength criteria and also impose the the need for a fatigue evaluation.

Through careful definition of where and how the operator attaches to the load carrying system, AFD engineers were able to steer the design team towards a simplified route to certification by categorising the majority of the basket structure as NHEC, i.e. non-human external cargo, thereby avoiding the more rigorous airworthiness requirements.

Finite Element Analysis

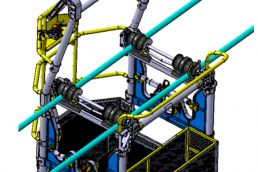

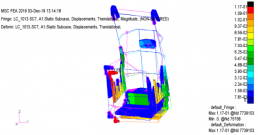

Two standards of Finite Element Model (FEM) of the basket were assembled: one for In-Transit conditions; one for On-Station conditions, each having entirely different constraints.

The baskets experience rather complicated loading scenarios involving inertia, operator placement and fall, aerodynamics, basket pitch and roll, and abuse conditions. Constraining the model also proved challenging requiring novel methods to avoid mechanisms whilst at the same time being realistic.

The model was used to establish loads and stresses in critical parts.

Stress Analysis For Type 4A Basket

The stress analysis considered both LIMIT and ULTIMATE loads and derived Reserve Factors against material strength and joint strength for each component.

For material strength, the general approach involved comparing principal stresses, extracted from the FEM, or derived by hand, with material ultimate strength (Ftu). For LIMIT load, von Mises stresses were compared with material yield strength (Fty).

For joint strength, interface loads extracted from the FEM were used to derive applied fastener tension and resultant shear loads alongside component bearing and pull-thru loads. These were then compared with fastener allowables and material bearing and shear strengths.

Testimonial

Gordon Bailey – Chief Designer

“Following on from a successful certification campaign for Basket Types 1 to 3 and the associated Load Carrying System it was decided to award AFD a contract to perform the analysis on Basket Type 4A, arguably the most technically challenging of the six types. AFD demonstrated they had the technical ability, tool-set and resource to compile, check and verify the entire analysis and did not disappoint with their timely delivery and trouble free submission to the EASA STC panel”.