Capabilities

Our core capabilities cover traditional static stress analysis (hand calculation), FEM (Finite Element Modelling), and F&DT (Fatigue and Damage Tolerance) evaluation.

We also provide support in the assessment of vibration, bird strike, and aerodynamics, including computational fluid dynamics.

For traditional static stress analysis, we use a combination of hand-calculations, MATHCAD computation, Excel Spreadsheets, and PYTHON scripting to check the strength of metallic, non-metallic, and composite structures.

We perform analysis to suit the client needs whether this be initial sizing to support conceptual design phases, or final design calculations to support project certification submissions.

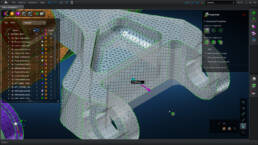

Our primary finite element modelling tool is MSC ONE with PATRAN and APEX pre and post-processors and NASTRAN code. This provides an advanced meshing and generative design capability that streamlines CAD clean-up and simplifies the meshing and modelling workflow.

Our engineers are highly familiar with the techniques employed for modelling airframe thin-walled structures using beam and shell elements (e.g. major fittings) using 3D TET or HEX solid elements.

We perform Fatigue Analyses using either a stress-based (s-N) or strain-based (e-N) approach and develop the necessary analysis tools from first principles to suit the analysis requirements and needs of the customer.

For Damage Tolerance we conduct a crack growth assessment using in house scripts, client-supplied software, or commercially available tools such as AFGROW or NASGRO.

We have extensive knowledge in the F&DT assessment of fuselage penetrations for antenna feed throughs and the substantiation of modified Fatigue Critical Structure.

Phillip Le MottéeHead of Structures

With over 40 years of experience in the Aerospace and Defence sector, Phill is a Stress and Structures subject matter expert and CVE. After obtaining a HND in Mechanical Engineering at Manchester Polytechnic, Phill joined Marshall of Cambridge in 1983 as a trainee Stress Engineer.

He then later joined BAE Systems, Air-weapon division in 1988, three years later he transitioned to a consultant stress engineer. In 1983 Phill returned to Marshall as a Lead Stress Engineer.

He possesses a broad understanding of the function of our business and having closely supported functional heads across design throughout his career he has been able to give subject matter expertise, coaching and oversight across many projects. In the period of 2006-2021 he acted as deputy to the Head of Stress / Head of mechanical engineering.

Phill was given Stress Check signatory in 1993 and MRB signatory for Gulfstream on the GIV Cargo conversion project in 1993. His CVE signatory was approved in 2007 and he has acted as CVE on numerous projects with a continual CVE activity since then. In the last five years he has been primarily acting as a consultant, CVE and checker along with coaching young engineers.