Task Objectives

Airframe Designs was engaged by GVH Aerospace to assist with the design, development, and certification of the Swiss Rotor Solutions Maximum Pilot View Kit (MPVK).

The kit provides enhanced pilot visibility for aerial lifting operations and reduces the pilot’s workload.

The Maximum Pilot View Kit comprises a replacement RHS composite door with an integrated bubble window; a modified floor structure; and a lower cowling with an integrated window.

The objective was to certify a door designed with a Carbon Fibre surround to meet EASA CS-27 airworthiness regulations.

The design of the new door frame was carefully specified to ensure that the necessary strength and stiffness characteristics were achieved. Particular attention was paid to the lay-up, stacking sequence, edge-band thickness, and Tg (glass transition temperature).

Loads Mapping

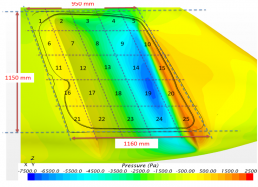

In order to define a static test for the door, it was necessary to map the aerodynamic suction over the surface and compartmentalise the loads for the static test.

Static Testing

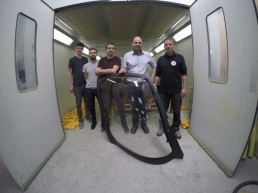

Once the design was sufficiently mature, and the loads clearly understood, a prototype or first article door was manufactured and prepared for a static test.

A rig was also designed to support and load the door. The loading fixture resembled a milk crate, permitting the placement of lead shot in discrete compartments to simulate the varying pressure distribution.

Testing was carried out in an approved test facility and inside an environmental chamber so that the test could be executed at an elevated temperature of 72°C.

Pass / Fail criteria were assessed during and after the test to ensure that the necessary compliance was achieved.

Static Strength Substantiation

The static strength of the entire door and interface with the helicopter was substantiated using the results from the static test.

The ULTIMATE test loads were increased to include knockdown factors to account for the absence of in-service moisture absorption and variability associated with composite materials and manufacturing processes.

Testimonial

(Jaco Loubser – GVH Project Manager)

“AFD were able to bring extensive experience in composite design and structural testing to this programme. During the test campaign, the AFD CVE/Witness diligently carried out the duty of ensuring test article conformity and executing the test according to the Test Plan. Post-test, AFD processed the results and delivered the required documents without delay, enabling GVH to issue the Supplemental Type Certificate in a timely manner”.