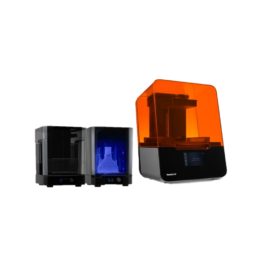

Airframe Designs are proud to unveil the latest addition to our comprehensive suite of additive manufacturing solutions: the FormLabs Form3 Plus printer. Following on from our recent post on the acquisition of two Bambu Labs X1E printers, this further underscores our continued commitment to precision, quality, and innovation.

The Form3 Plus printer stands out in the field of additive manufacturing due to its high-resolution Stereolithography (SLA) technology, which enables the production of parts with fine detail and surface finish, down to a layer height of just 25 microns. This cutting-edge resin printing capability allows us to push the boundaries of what’s possible, particularly in wind-tunnel models, composite tooling, and smart tooling applications.

Our ability to produce intricate, and highly accurate components is significantly bolstered by the Form3 Plus. This precision is important for the aerospace industry, where every micron matters. The printer’s advanced SLA technology ensures that we can create mock-ups, trial parts, and final products that meet the exacting standards required for aerospace applications.

The Form3 Plus’s versatility extends to the creation of composite tooling and smart tooling, enabling us to innovate in the design and manufacturing of lightweight yet durable components. These advancements are vital for the development of next-generation aerospace technologies, offering potential improvements in performance, efficiency, and safety.

The Form3 Plus facilitates the rapid production of wind-tunnel models, allowing for faster iteration and validation of aerodynamic designs. This capability accelerates the development cycle, enabling our engineers to refine and perfect designs with an efficiency previously unattainable.

As we integrate the FormLabs Form3 Plus printer into our operations, we are setting new standards for precision and flexibility in aerospace manufacturing. This investment is not just about enhancing our technical capabilities; it’s about delivering superior solutions to our clients, ensuring that we remain at the cutting edge of aerospace engineering and additive manufacturing.

Airframe Designs are exploring the numerous possibilities opened up by the Form3 Plus printer and our commitment to innovation, quality, and excellence in engineering continues to drive us forward. With this latest addition, we are more equipped than ever to meet the evolving needs of our clients and the industry at large.

Take an exclusive look at the HP42 model aircraft, a current project of our senior design engineer, Andrew White. The propellers, were printed on the Form3 and Andrew is very happy with them.

If you didn’t catch our previous post showing a video of Andrew’s model Vulcan flying, it’s well worth checking out HERE.

For more information on how Airframe Designs can help you with your next project, please get in touch.